(BUS06131) Operations and logistics management assignment analysing the problems related to logistics procedure at ZARA

Question

Task: In your operations and logistics management assignmentidentify how operations and logistics management contributes to an organisation’s strategic and operational performance. Critically evaluate the role of logistics management in operations management. Analyse the organisational requirements for effective operations and logistics management in Zara’s operations. Assess the market; technological and data-driven changes that impact on the areas of operations and logistics at Inditex Global

Answer

Introduction

The major objective of the operations and logistics management assignmentis to conduct an investigation into the logistics procedure used by ZARA in order to pinpoint any problematic areas and provide recommendations for appropriate enhancements. Therefore, the operations and logistics management assignmentwill include information on the company's supply chain management procedures both in the past and in the present in order to emphasise the differences and track the discrepancies that are now present. In the area of supply chain management, offering workable solutions and suggestions to the business's plans will need a detailed examination of incoming and outgoing logistics, as well as an awareness of the function that information flow plays inside the organisation. This will contribute. The operations management of Zara, a Spanish retail business, is the topic of discussion in this particular operations and logistics management assignment. In addition to this, it will be shown how the principles of operations management are implemented at Zara. The recommendation and conclusion, which comes at the end of the operations and logistics management assignment, summarises the findings of the essay and provides recommendations for areas of development.

Operations and logistics management contributing to Zara’s strategic and operational performance discussed in the operations and logistics management assignment

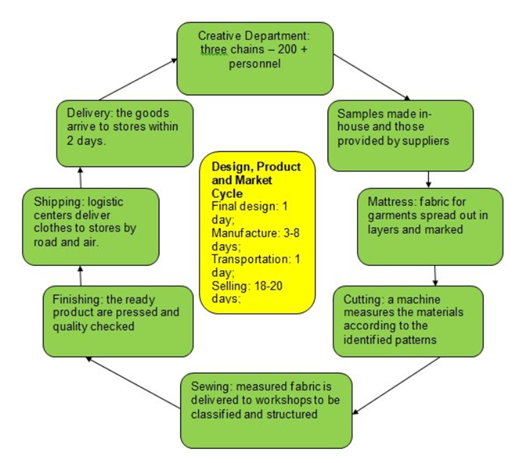

The idea behind the network's supply management is intricately linked to the notion of time-based competition, which enables the network to source items on an international scale. Sarkeret al., (2022) stated that the team's understanding of the most prominent fashion trends is shaped further by the constant input of EPOS data from Zara's shops located all over the globe. In addition, the operations and logistics management assignmentexperts in marketing continue to examine the suppliers about the pricing, charges, and margins. A global sourcing strategy offers a diverse selection of fabric that is sourced from a number of different nations in order to facilitate the process of determining the production volume and setting the deadlines. As per the operations and logistics management assignment findings this strategy cuts the risk of delays greatly since there are many additional fabric makers that can be relied on in the event that one of the suppliers is unable to fulfil their order. As a result, around forty percent of clothing are brought in from other countries, while the remaining sixty percent are made in Spain (Sweeney and Waters, 2021). In addition, the completed goods are given their final prices and labels in the distribution centre of the firm, which is located in La Coruna. In order to achieve a time-based competitive advantage and triumph over its competitors in North America and Europe, it is found in the operations and logistics management assignment that the full manufacturing cycle takes two weeks to complete.

Figure 1: Flow and Cycle Diagram Identifying the Flow of Materials, Money, and Product

(Source: Barton, 2019)

The firm discussed in the operations and logistics management assignmenthas retained its position as one of the wealthiest companies in the fashion sector based on sales and is able to achieve financial success thanks to the innovative strategies that are used in the administration of its operations. The business was an early innovator in the field of fast fashion, and now, as a result of its vertical integration, it is able to fulfil client orders in a very short amount of time (Cui and Fan, 2021). Good IT solutions provide enough security for stock control. At this time, the company's use of information and communication networks yields financial benefits to operations and enables it to adhere to the essential idea of responding rapidly to variations in demand. As per the operations and logistics management assignment due to short lead-time, changing fashion trends, and limited resources, the company's management must be able to create production deadlines fast while yet maintaining success and flexibility. Overall, Zara's inventory strategy rests on the following three pillars: stock on hand, stock in the warehouse, and a demand prediction that is tightly managed by the creative departments (Sumukadas, 2021). As per the operations and logistics management assignment the organisation is able to generate strong sales and interest among its clients thanks to the use of information technology, inventory management, and supply chain management.

Role of logistics management in operations management of Zara

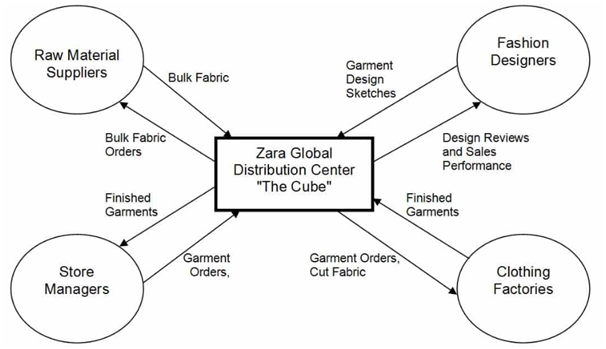

According to Felipe Caro, centralization is the secret to Zara’s success. As per the given case study, Zara maintains a consistent, rapid, and regular rhythm that is centred on the delivery of orders to retail locations. It is found from the operations and logistics management assignment that every Zara store sends in two orders a week at predetermined times and on certain days. It is becoming ever more important for businesses to ensure they have a supply chain that is well managed and maintained (Sitaro, 2020). This information, in conjunction with other factors to take into account, will indicate how Zara is able to make items of such great quality at costs that are so much lower than those offered by the company's rivals. The most important prerequisite for the successful implementation of integrative and collaborative activities is the efficient sharing of information. As per the operations and logistics management assignment in contrast to the conventional method of placing an order, Zara merchants offer the manufacturers with all of the essential information, which would be hard to process manually.

Zara is able to reduce the risk of overproduction thanks to the use of intranet networks, which allow for a continuous flow of information. Integration across different corporate operations adds to the development of information dissemination, which in turn leads to a real gain in performance and productivity (Ahmad and Miskon, 2019). As per the operations and logistics management assignment implementing workflow information systems may increase data sharing, promote transparency, and ensure accurate communication, all of which contribute to the core goal of an ERP system, which is to combine information and activities from different functional divisions of a business. This is because an ERP system's main purpose is to coordinate efforts throughout the organisation.

Figure 2: Supply Chain Operations of Zara

(Source: Hugos, 2020)

López et al., (2021) states in the operations and logistics management assignmentthat Zara does not manage and optimise individual elements of the supply chain but rather controls and optimises the whole chain as a whole, despite the fact that this may raise costs at certain levels. Zara maintains a steady, regular, and rapid rhythm that is centred on the delivery of customer orders to retail locations. Trucks only depart at the times that have been scheduled, and shipments only enter the stores at the periods that have been scheduled. The garments are already hung up, branded, and priced before being shown (Shabir and AlBishri, 2021). Zara is able to respond to swings in weekly and monthly demand because to the vast and technologically advanced facility that they use, which also has spare capacity. For instance, normally, Zara is open for business for 4.5 days a week, 24 hours per day. Extra shifts and temporary employees are hired as needed. As per the operations and logistics management assignment findings, in an industry where the norm is six months, it is fascinating to see that Zara can bring a product from concept to store in only fifteen days. This is due to Zara's innovative approach to design and manufacturing, which has made the company a leader in the industry by providing a new standard to strive towards.

The organisational requirements for effective operations and logistics management in Zara’s operations

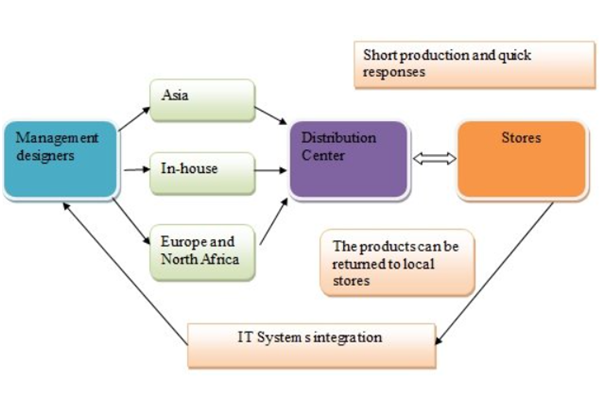

Zara's emphasis on originality and quality, along with its operational objectives of reducing lead times, decreasing inventory, and increasing the diversity of styles available, is a major factor in the company's current competitive edge. As per the operations and logistics management assignment by incorporating the bottom-up viewpoint of strategy into its operations, Zara was able to increase its innovativeness in a rapidly evolving market. As a crucial source of competitive advantage, the regular introduction of new goods that provide consumers perceived value is essential. Rather than relying just on industry-wide trends, Zara also took use of client feedback and recommendations to design fashionable items (Waters, 2019). The ability of Zara shop managers to relay client input on preferences directly to corporate was another bottom-up tactic used by the company. It is found from the operations and logistics management assignment that this allowed Zara to be more competitively nimble in its copying and marketing of items to coincide with new trends in the fashion industry, resulting in more realistic sales estimates and faster product releases.

As a result of being involved in every phase of the production process, from initial concept to final sale, Zara is in a unique position to beat out the competition. The purpose of implementing this strategy is to raise service delivery and value providing while lowering operating expenses (Dang, 2022). Fashion shows and other similar forms of influence promotion for next season's trends are being phased out in favour of Zara's focus as a fashion imitator was on comprehending the changing fashion trends, aligning these changes to meet the wants of its customers. About 500 local suppliers located near Zara's La Coruna headquarters do all the other manufacturing tasks. The business takes advantage of manufacturing that is nearshored and situated in close proximity to the distribution headquarters in Spain (Schabasser, 2022). As per the operations and logistics management assignmentZara is able to give frequent small-batch deliveries because to its centralised logistics system. These deliveries always make it to the shops on schedule. The effective delivery of things to the shop that have already been branded and priced is made possible when the business owns the whole process. Because of the deeply ingrained and consistent regularity of these deliveries, it is possible to organise and manage other duties around them, which has a favourable impact on both the productivity of the workers and the profitability of the business.

Figure 3: Vertical Supply Chain of Zara

(Source: Barton, 2019)

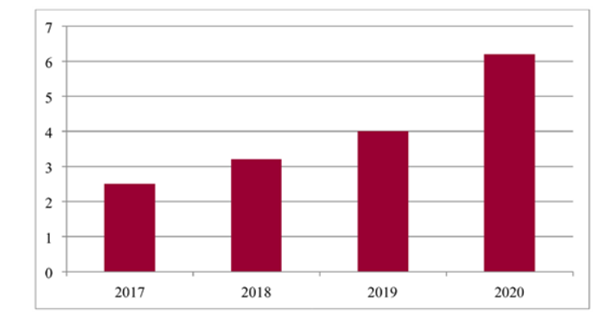

It is analyzed from the operations and logistics management assignment that Zara maintains an agile approach that is capable of being optimised with a vertical structure; designs are able to change into trend-dependent goods that are on the shop shelf in a couple of weeks. Because of the fact that around 85 percent of their production capacity is set aside for the capability to make in-season stock modifications, the brand is able to maintain its adaptability with regard to frequency, amount, and variety (Fridley, 2018). The capacity to react to needs nearly in real-time has resulted in an astounding sell-through rate for the brand. Eighty-five percent of Zara's stock is sold at full price, which is far higher than the norm for the industry. On the list of the most valuable brands compiled by Forbes for 2020, the company's brand comes in at number 41, just behind Ikea. As per the operations and logistics management assignment this marks an improvement from 2019, when the company's ranking was number 46. This was during the epidemic phase of the disease (Ha, 2021). Zara was successful throughout this challenging year in part because it has a strong online sales section; the firm intends to close one thousand locations so that they may concentrate on boosting their online sales even more.

Technological and data-driven changes that impact on the areas of operations and logistics discussed in the operations and logistics management assignment

Inditex is the parent company of the Zara retail chain and is the biggest clothes retailer in the world. Its competitors are producing clothing at a faster rate, taking as little as one week from the moment of creation to the point of sale, and they are updating their websites every day with hundreds of new products (Caro, et al., 2019). As per the operations and logistics management assignment analysis the Spanish business is working to maintain its competitive advantage by creating innovative technologies, forming partnerships with other technology companies, and recruiting talented individuals from start-up companies. If such initiatives are successful or unsuccessful, it may help decide whether or not Inditex can adjust to the shifting environment of the garment retail industry, which may soon see Amazon replace Macy's as the largest retailer of clothes to customers in the United States. In the 1980s, Zara was an industry pioneer in the fast-fashion movement. It was the first business to create a system for quickly adapting to ever-changing styles. As per the operations and logistics management assignment to do this, the company created flexible supply chains that relied on regional manufacturing facilities near its headquarters (Song, 2021). This cut its "lead times," or the period from the start of the design process until a product is in shops, down to about three weeks.

Zara has its own centralised distribution system in the United States. Under very stringent time limitations, the information technology implementation of the operation study calls for the establishment of dynamic access to calculate many big live datasets. Because of this, Zara is able to replace almost three-quarters of the goods that is on display every three to four weeks, and the average amount of time that customers wait between visits to Zara shops is 17 times per year, which is higher than its rivals (Bilovodska, et al., 2018). However, it is found from the operations and logistics management assignment that new entrants to the market that are expanding rapidly and are not constrained by vast store estates are moving manufacturing much closer to distribution and are continually updating inventory. At this juncture, vertically integrated methods of managing supply chains need for supply chain management solutions that are capable of assimilating data from operational applications (Xuejie, et al., 2019). The corporation may choose to implement technical solutions that combine the examination of data supplied from both within and outside the organisation in order to solve the problems posed by remote data processing. As per the operations and logistics management assignmentthe ideas that have been offered do not create any discernible modifications to the organization's existing vertically integrated supply chain systems.

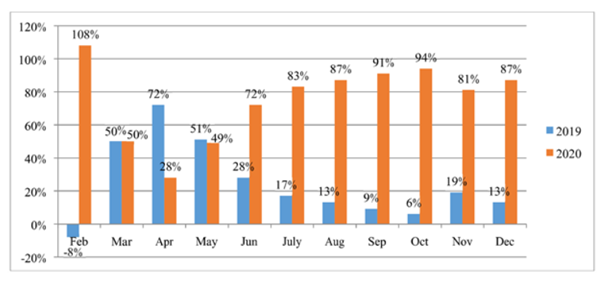

Figure 4: Online Sales of Inditex (Zara) from 2017 to 2020

(Source: Shabir and AlBishri, 2022)

A vertical supply chain is used by the operations of Inditex, which is regarded as a highly unconventional and one-of-a-kind business approach in the fashion sector. It is analyzed from the operations and logistics management assignment that as a result of the decision made by the firm to handle the process of design, manufacturing, and distribution completely in-house, the retail locations owned by the company are able to respond to shifting fashion trends far more quickly than those owned by the company's rivals (Zhu, 2022). As a result of the approach for managing the supply chain, consumers are encouraged to frequent the store at a rate that is four times higher than that of their rivals. As per the operations and logistics management assignment this creates a better level of wearability. Therefore, the only thing that the management of Zara needs to do is build a second retailing centre with a structure identical to the first. The presence of an extra retailing department may relieve the headquarters of certain obligations and provide the company a better degree of control over other areas. The coordination issues that arose between the newly established centres will be resolved once the necessary information technology systems are merged. In addition, the process of reorganisationas per the operations and logistics management assignmentwill have an impact on the realm of design since the American department will be especially directed on web-based supply chain process when the reorganisation is complete (Su, 2020). As a consequence of this, a portion of the tasks will be delegated to this department, and as a direct consequence of this, there will be designers who focus on various geographical locations.

Figure 5: Inditex Financial Report

(Source: Shabir and AlBishri, 2022)

Conclusion and Recommendations

It is found from the operations and logistics management assignment that the efficiency of a well-known retailer's plans to expand into new markets throughout the globe may be jeopardised if too much emphasis is placed on systems of vertical integration. In this regard, Zara need to establish a number of different creative divisions that would be responsible for controlling various locations. As per the operations and logistics management assignment an examination of Zara's operations reveals that quality management, location and sustainability, and supply chain management are the primary domains in which the company makes decisions. In this age of quick-change fashion, To gain a competitive edge, Zara has built a highly efficient and well-connected system of factories. E-commerce, facility expansion, ECR system

implementation, increased advertising and providing activities across all markets served, and a commitment to sustainable design among others are all suggested as means by which the corporation might boost its operational performance. As per the operations and logistics management assignment due to the fact that the department would be primarily directed on a certain ethnic group, the reorganisation has the potential to significantly enhance the expectations placed by customers. Therefore, the centres may be coordinated via the use of electronic data interchange methods that are integrated by ERP systems. These systems provide more control and boost production volumes all over the globe. Overall, this kind of approach mentioned in the operations and logistics management assignmentstrengthens Zara's position as the market leader.

References

Ahmad, S. and Miskon, S. (2019). The Adoption of Business Intelligence Systems in Textile and Apparel Industry: Case Studies. Advances in Intelligent Systems and Computing, [online] pp.12–23. Available at: https://link.springer.com/chapter/10.1007/978-3-030-33582-3_2 [Accessed 30 Nov. 2022].

Barton, S. (2019). ZARA: Analysis of Logistics Systems - 2578 Words | Report Example. [online] Free Essays. Available at: https://ivypanda.com/essays/zara-analysis-of-logistics-systems-report/ [Accessed 30 Nov. 2022].

Bilovodska, O.A., Saher, L.Y. and Syhyda, L.O. (2018). Supply chain management: world’s companies experience. essuir.sumdu.edu.ua. [online] Available at: https://essuir.sumdu.edu.ua/handle/123456789/70707 [Accessed 1 Dec. 2022].

Caro, F., Babio, F. and Peña, F. (2019). Coordination of Inventory Distribution and Price Markdowns for Clearance Sales at Zara. Springer Series in Supply Chain Management, [online] pp.311–339. Available at: https://link.springer.com/chapter/10.1007/978-3-030-20119-7_13 [Accessed 1 Dec. 2022].

Cui, Y.C. and Fan, B.F. (2021). The corporate social responsibility strategy in fast fashion industry : case company Zara. [online] www.theseus.fi. Available at: https://www.theseus.fi/handle/10024/512245 [Accessed 30 Nov. 2022].

Dang, D. (2022). Artificial intelligence: AI in fashion and beauty e-commerce : Zara, Sephora. [online] www.theseus.fi. Available at: https://www.theseus.fi/handle/10024/783204 [Accessed 1 Dec. 2022].

Fridley, L. (Lila J. ) (2018). Improving online demand forecast using novel features in website data : a case study at Zara. [online] dspace.mit.edu. Available at: https://dspace.mit.edu/handle/1721.1/117976 [Accessed 1 Dec. 2022].

Ha, J. (2021). Zara Strategic Analysis. Honors Theses, University of Nebraska-Lincoln. [online] Available at: https://digitalcommons.unl.edu/honorstheses/290/ [Accessed 1 Dec. 2022].

Hugos, M. (2020). Zara Clothing Company Supply Chain. [online] SCM Globe. Available at: https://www.scmglobe.com/zara-clothing-company-supply-chain/ [Accessed 30 Nov. 2022].

López, T., Riedler, T., Köhnen, H. and Fütterer, M. (2021). Digital value chain restructuring and labour process transformations in the fast fashion sector: Evidence from the value chains of Zara & H&M. Global Networks, [online] 22(4). Available at: https://onlinelibrary.wiley.com/doi/full/10.1111/glob.12353 [Accessed 30 Nov. 2022].

Sarker, S., Rashidi, K., Gölgeci, I., Gligor, D.M. and Hsuan, J. (2022). Exploring pillars of supply chain competitiveness: insights from leading global supply chains. Production Planning & Control, [online] pp.1–18. Available at: https://www.tandfonline.com/doi/abs/10.1080/09537287.2022.2145246 [Accessed 30 Nov. 2022].

Schabasser, C. (2022). Benchmarking fast fashion supply chains: Identifying enablers of operational excellence. London Journal of Social Sciences, [online] 2(4), pp.13–19. Available at: https://londonic.uk/js/index.php/ljbeh/article/view/85 [Accessed 1 Dec. 2022].

Shabir, S. and AlBishri, N.A. (2021). Sustainable Retailing Performance of Zara during COVID-19 Pandemic. Open Journal of Business and Management, [online] 09(03), p.1013. Available at: https://www.scirp.org/html/3-1531766_108440.htm#ref19 [Accessed 30 Nov. 2022].

Shabir, S. and AlBishri, N.A. (2022). Redirect Notice. [online] Google.com. Available at:

https://www.google.com/url sa=i&url=https%3A%2F%2Fwww.scirp.org%2Fjournal%2Fpaperinformation.aspx%3Fpaperid%3D108440&psig

=AOvVaw0rcHGJRLUYAonfbuQi8xiK&ust=1669918605938000&source=images&cd=vfe&ved=0CBAQjRxqFwo

TCJj6odzB1vsCFQAAAAAdAAAAABAX [Accessed 30 Nov. 2022].

Sitaro, T. (2020). Fast Fashion and Sustainability - The Case of Inditex-Zara. Senior Theses. [online] Available at: https://research.library.fordham.edu/international_senior/46/ [Accessed 30 Nov. 2022].

Song, X. (2021). Research on Cost Control of Enterprise Supply Chain--Taking ZARA as an Example. [online] Available at: https://webofproceedings.org/proceedings_series/ECOM/IEMB%202021/Y0314.pdf [Accessed 1 Dec. 2022].

Su, Y.-Z. (2020). The Internationalization Strategies of Fast Fashion Clothing Retailer Brands: A Cases Study of ZARA, H&M, UNIQLO, and Gap. [online] Available at: https://c030.wzu.edu.tw/datas/upload/files/2020%E7%95%A2%E6%A5%AD%E7%94%9F%E8%AB%96%E6%9 6%87/108GP_1105209030_%E8%98%87%E7%BE%BD%E7%94%84.pdf [Accessed 1 Dec. 2022].

Sumukadas, N. (2021). Are you ready for your next product recall crisis Lessons from operations and supply chain management. Business Horizons. [online] Available at: https://www.sciencedirect.com/science/article/abs/pii/S0007681320301531 [Accessed 1 Dec. 2022]. Sweeney, E. and Waters, D. (2021). Global Logistics: New Directions in Supply Chain Management. [online] Google Books. Kogan Page Publishers. Available at: https://books.google.co.in/bookshl=en&lr=&id=Bt4zEAAAQBAJ&oi=fnd&pg=PR1&dq=Operations+and+logistics +management+contributing+to+Zara%E2%80%99s+strategic+and+operational+performance&ots=_IM067WMs4 &sig=1zZBGsgEpVLjS-HldyvXoKHyKp4&redir_esc=y#v=onepage&q&f=false [Accessed 30 Nov. 2022].

Waters, D. (2019). Supply Chain Management: An Introduction to Logistics. [online] Google Books. Bloomsbury Publishing. Available at: https://books.google.co.in/bookshl=en&lr=&id=kyJHEAAAQBAJ&oi=fnd&pg=PT13&dq=The+organisational+ requirements+for+effective+operations+and+logistics+management+in+Zara%E2%80%99s+operations&ots= S8H0iC81fJ&sig=0IIbDHTCgOli_qsBrob8IjoY06o&redir_esc=y#v=onepage&q&f=false [Accessed 1 Dec. 2022].

Xuejie, C., Chang, Q. and GuangHao, Z. (2019). Research on Innovation supply chain Management in Fast Fashion Industry——A comparative analysis of ZARA and H&M. Proceedings of the 2019 3rd International Conference on Education, Culture and Social Development (ICECSD 2019), [online] 344.

Available at: https://www.atlantis-press.com/proceedings/icecsd-19/125916550 [Accessed 1 Dec. 2022].

Zhu, T. (2022). International Business Strategy of fast fashion Brands (On the example of Zara). Journal of Education, Humanities and Social Sciences, [online] 4, pp.221–227. Available at: https://drpress.org/ojs/index.php/EHSS/article/view/2770 [Accessed 1 Dec. 2022].