Laboratory Test for Evaluation structural performance of composite beam

Question

Task:

1. Investigate the impact of fatigue effect on ultimate capacity of composite beam (I Joist)?

2. Investigate the influencing factors for both ultimate capacity and fatigue testing.

Answer

Introduction

The composite material uses for industrial applications for different purpose and enhance overall performance in various terms such as safety, reliability, cost reduction, enhance strength etc. the composite material can replace regular construction material such as steel, concrete etc. by considering key aspect and key features. Before, selecting suitable material, it is require evaluating the characteristics and mechanical properties. Therefore, it is require testing the material using standard material testing procedure. The result obtain from the testing procedure gives the correct information and guides to select the suitable material for specific application. The testing procedure may be destructive and non-destructive; it depends on requirement and quality assurance of material. In this report, there are two destructive test perform in laboratory to identified the behavior of composite beamBaylor, G. (2011).

Standard Equipments and standard specimen for test

• Hydraulic actuator

• Test specimen i.e. I-Joist

• Laboratory standardequipment such as clamp, stand etc.

• Laboratory test software.

• I-joist timber beam standard specimen for testing.

Beam details:

1. Beam span: 2000 mm

2. Height: 300 mm

3. Flange: 70 x 45 mm

Laboratory test procedure: 1

The first beam will loaded till failure occurs to establish the ultimate loading capacity The standard specimen keeps vertically in between the hydraulic actuator. After that the pressure applied to the specimen at one ends as considering vertical stress only. The pressure applied over the top segment of I-joist vertically downward. Therefore the compression stress induces to the test specimenFillingham, T. (2013). The magnitude of load increasing cumulative until the first fatigue crack is not observed. The computer application stores data i.e. deflection and applied load.

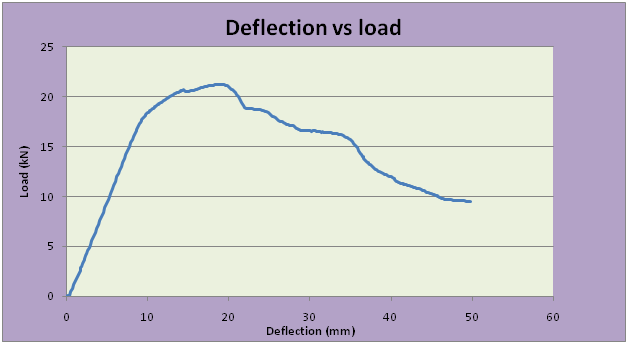

The above graphs plotted from the data which obtain from experiment. It observes that the load value increases at specific level and reduces drastically. The maximum magnitude highlights the ultimate strength of the I-joist timber beamHarte, A. (2013).

Laboratory test procedure: 2

The second beam first goes under 1000 cycles of 6 kN cyclic load and then tested under the static point load.

In this case, the I-joist timber is placed between the hydraulic actuator two times. Firstly, it is require to test the beam for 1000 cycle as applied 6 kN load over the test specimen. Next, the I-joist beam has been tested similarly as perform in test 1. The static load applied over the timber beam and allows raising load until first crack is not observed. The data obtain from test needs to save and compute diagram as load vs deflectionVandoren, B. (2018).

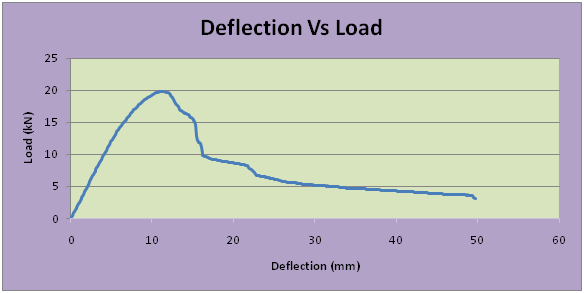

The above diagram obtained from the experiment 2, itobserves that the load capacity or ultimate strength of material is reducing compare to previous case. This is obvious due to fatigue and static load applied over the test specimen. The ultimate load observes below 20 kN as highlight peak of graph.

Conclusion

In this report, there are two experiment perform with same material but different procedure. In first case, the ultimate strength observe over 20 kN as static load applied over specimen. In second case, the dual load applied i.e. static and fatigue therefore the strength of specimen reduces. From this, it concludes that the timber material strength reduces due to multiple applied loads.

References

Baylor, G. and Harte, A. (2013).Finite element modelling of castellated timber I-joists.Construction and Building Materials, 47, pp.680-688.

Harte, A. and Baylor, G. (2011). Structural evaluation of castellated timber -joists. Engineering Structures, 33(12), pp.3748-3754.

Steensels, R. and Vandoren, B. (2018). Experimental and Numerical Analysis of Timber I-Joists with Cut-Outs. Proceedings, 2(8), p.463.

Zhang, B., Kermani, A. and Fillingham, T. (2013). Vibrational performance of timber floors constructed with metal web joists. Engineering Structures, 56, pp.1321-1334.