Functions Of A PLC Controller In Networking

Question

Task 1:

Provide a short note on various forms of signals practices in managing and manipulating the control over programmable logic. While providing the description, attempt the below-provided deliverable:

Analogue

Digital (include Discrete)

Task 2

Clarify the similarity and differences between the analog inputs and outputs concerning the word length. While elucidating reckon with the below-given criteria.

10-bit

12-bit

Task 3

Evaluate various protocols used in the process of signal communication using the format of a table.

Task 4

Describe various ways and standards to be followed in the process of networking. The below points should be covered in your description:

Master to Slave control

Peer to Peer networks

7-layer ISO model

IEEE 802

Manufacturing Automation Protocol (MAP)

Answer

Examine the various type of Signals utilized in the programmable logic controller.

Analogue

The term analog signal signifies the electro-magnetic waveform that unceasingly changes and fluctuates its amplitude concerning time. The name of this sort of wave signifies the ability of it to transfer the user data. If taken an instance, the fluctuation in the voltage over the electrical signal would make a proportionate change over the channel of telephone line which would subsequently make a variation in the power input of the speaker and crate appropriate sound waves for the proper communication. The analog type of waves retains some of the physical property which aids in helping it to transfer the required data or information. The property of voltage or potential difference is the one that is utilized most in the field of telecommunication since it is very apt in conveying the desired data to the concerned person. The voltage is being manipulated using a transducer in the system that in result would transform one form of energy into another form. If taken the instance of normally working microphone, the sound waves when impact on the diaphragm makes vibration and hence a small electromotive force is generated in the coil. Hence the sound energy is being converted into electric energy and the signal is sent to the amplifier which amplifies the signal and sends it to the speaker. The particles of carbon also play a crucial part in maintaining the features and clarity in the signal since with each vibration, the density of carbon changes along with its resistance which makes appropriate compressions and depressions to propagate desired sound waves. Although the continuous occurrence of the change in the signal would make it very hard to identify or filter the glitches or other noises in the channel. Because of the presence of the process called signal attenuation the signal gets further worse with the length of course.

Hence from the above section of this plc controller report, it could be very clear that the signals of analog classification are very fluctuating in characteristics, thus similar to the trough and crust of the transverse wave it has a positive and negative peak. Between these two limits of positive and negative value there are very significant multitude values that could be represented by many variables. By using the channel of analog signals, the data could be deduced from various stages. We could also take the examples of the microwave oven which could increase the temperature of an object at the desired period. If the required temperature or the maximum temperature to be set in the oven is to be 300 degrees Celsius then the course of units in the analogs system could be partitioned into 300 parts. The PLC controller would help the oven to systematically attain the desired temperature. Each step in the temperature rise would be determined by the data set of 8 bits, by which a combination of 256 ways could be made and the maximum temperature of 300 could be attained from the basic temperature of 0. In this process, the data of 8 bits are manipulated in such a way that the required temperature is acquired and thus this data is sent to the microprocessors and at last the work is being transferred on the object to be heated. From this situation, it could be deducted that the analogous signals could be utilized in providing order or pieces of information regarding the control of factors like pressure, temperature, level, position, etc. These pieces of information and orders could be preloaded in the system of the machinery so that when needed these options could be automatically loaded to control the activity of mechanical parts like motors, valves, vibrating sections, etc.

Digital, Including Discrete

The method of the digital is mostly in the binary form which signifies the orders to switch on or off the concerned circuit which is technically represented by the digits 1 and 0 respectively. If taken very logically the idea of digital signals it just switches on and off the concerned parts like motors, transistors, etc. The term bit is used to represent the set of digital signals that are termed to be a bit. The information is being passed to the processing unit and it is being sent to the concerned hardware to make it on and off according to the binary information sent. The instance of this could be discussed in the motor working on the types of machinery of a crane since the wire on the motor would only be rotated to give out a certain length as per the command is given from the plc controller. The plc controller works on the bits loaded in the plc controller and also controls the speed of the operation so that the action could not be very abrupt. There would be al lot of binary combinations to carry out a specific activity and hence it is a very complex method to decode the binary machinery language. The mechanical process in the big industries are not being controlled directly and are thus indirectly managed by using a plc controller.

Similarity and differences between the analog inputs and outputs concerning the word length

The concept of the word length is the size of it, which could be represented using the units of bits which could be represented as a universal collective of one unit which could be transferred altogether. By the channel of PLC controller, better interaction with the source of input and the destination of the output. The PLC controller makes it very convenient for the transaction of machinery input and interactive output. The Input of the interactive analogous message is converted into the digital message after it passes through the plc controller. The machine is equipped with the relevant card for the input in the respective rack. The multiple analogous commands go through this card and then are distributed to the various targets in the machine. In contemporary machines normally the card size of 4, 6, and 8 are used. The analogous system are manipulated by varying its voltage which would be later converted into the form of digital signals after it is passed through the plc controller. The message from the plc controller would be later converted from digital data to the form of analogous pieces of information by using digital to analog converter.

9 Bit

In the process of 9-bit classification, the single piece of analog input is being dissected into the word having the size of 9, which could be roughly denoted as the 9 representative bits in the form of a digital format.

10 Bit

In the process of 10 Bit classification, the single piece of analog input is being classified into the word string having the overall length of 10 bits in the arrangement of a digital format.

12 Bit

The methodology of the 12 Bit classification entails the inclusion of the single piece of analog input is being classified into the word string having the overall length of12 Bits in the digital format.

Protocols used in the process of signal communication using the format of a table.

The PLC controller works on the platform of 5 protocols which are USB, RS 232, RS 422, Ethernet, and IEEE 488. The protocols which are discussed above in this plc controller report consists of its advantages and disadvantages, which relies on the way it is implied in the process.

|

S.NO. |

PROTOCOL |

MAXIMUM SPEED |

MAXIMUM SPEED |

DEVICES |

BEST IN |

|

1 |

RS-232 |

Up to 50 m |

700 Hz |

1 |

|

|

2 |

RS-422 |

Up to 1000m |

700 Hz |

31 |

The maximum distance covered; the number of devices |

|

3 |

IEEE-488 |

UP to 2m |

1 MHz |

14 |

Maximum speed |

|

4 |

Ethernet |

185 m |

36000 Hz |

29 |

|

|

5 |

USB |

5m |

80 Hz |

8 |

|

Describe various ways and standards to be followed in the process of networking:

Master to Slave Control

The instruments of the plc controllers are normally included in the most modern machines which include the adept inclusion of any variant of the computers. The PLC controllers could only be used efficiently in the desired manner when they are integrated systematically. It is by using the PLC controller that the process of data acquisition and the processes in the interface of the operator, processing the sensitive data and the recording of the information carried out. It is by hosting the computer that the communication via Computer and PLC is done while reckoning the daisy wheel pattern. The network of PLC controllers keeps on transferring the relevant information to the required areas in the circuit so that the desired task should be carried out. In the network of the PLC controllers in the machinery, one of the plc controllers is considered to be a master PLC since the instructions to the subsidiary PLC controllers are being transmitted by it. This process is very fast and could not be observed by humans directly since in second several cycles of transmission takes place among these plc controllers. The subsidiary plc controllers which obtain the information form the master plc controllers are often termed to be a slave plc controller. The documentation software installed in the hybrid machinery would help the plc controllers in handling the heavy programming language. It is using the relay ladder logic, that the programs are written or loaded inside the plc controllers that enable the effective functioning of the machinery as a single unit. Hence the process is not an irreversible one and could be modified and upgrades of any glitches are present or there is an alteration required to cope with the new situation.

Peer to Peer Networks

The system of peer to peer network would disperse and reorganize the centralized system of command and facilitate the coordinated type of control. Every memory table in the machinery would be duplicated and the plc connectors would be connected in a daisy chain fashion. The data encoded in a single plc controller would be copied to another plc present in the same network and hence a coordinated flow of information happens as per the stipulations in the operating system. The respective plc controllers are endowed with the responsibility to control the specific sections of the machinery. Thus, the use of the plc controller would reduce the high complexities in the machinery process leading to a very efficient form of communication.

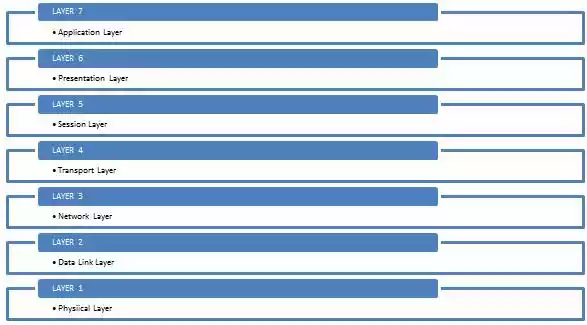

7 Layer ISO Model

A new stander called ISO or OSI was being devised by the International Standards Organization which would be very appropriate for the Open System Interconnection. This system would reduce the problems and hindrances existing in the current system and hence increases the efficiency of the interconnecting problems. Different protocols in standards, electrical, physical, etc. could be utilized to link the digital equipment present.

Figure: Layers in ISO

IEEE 802

This provision included in the family standards of IEEE would help in managing the LAN connections and MAN connections by enforcing the controlled limitations in the flow of packets in various sizes in the respective network. Hence the transfer of the data is done by transferring it to respective units or sections which be very uniform and simple. The various parameters and the flow of data are designed using the framework mentioned in the OSI model. Such physical and data layers in the framework would consist of the filter like MAC layers, Media and Control access control layers, and LLC layers.

MAP

To control and effectively manipulate the system of networks which may be designed by various individuals using the Manufacturing Automation Protocol. The tools like programmable controllers would help the system in dealing with both the compatible and incompatible forms of commands.

The parameters and the framework of the manufacturing automation protocol were revised many times and hence an upgraded version of MAP 3.0 was being introduced by the company in 1987. This system has been implied and promoted in their systems by many companies like General Motors, Ford, Boeing, etc. Although the framework had failed to attract the attention of many firms because of its limitations in the sections and qualities of the Ethernet. There were many limitations present in the aspects of the MAP 3.0 like difficulty in manipulation or alteration of the attributes of the protocols, liability in the modification of the links in MAP interface, etc.

Reference List

Bolton, W, 2009, Programmable Logic Controllers, Fifth Edition, Newnes, Elsevier Ltd.UK.

Parr,E, 1999, Industrial Control Handbook, Industrial Press Inc.

Laughton, M, Warne, D, 2003, (ed),Electrical Engineer's Reference book, 16th edition,Newnes, Chapter 16 Programmable Controller

Harms, Toni M. & Kinner, Russell H. P.E., 1989, Enhancing PLC Performance with Vision Systems. 18th Annual ESD/HMI International Programmable Controllers Conference Proceedings,

Maher, Michael J.1989, Real-Time Control and Communications. 18th Annual ESD/SMI International Programmable Controllers Conference Proceedings,

Erickson, Kelvin T., 1996, "Programmable logic controllers". Institute of Electrical and Electronics Engineers.

Iqbal, S., 2008, "Programmable Logic Controllers (PLCs): Workhorse of Industrial Automation". 68-69. IEEEP Journal: 27–31.

Petruzella,, Frank D., 2005, "Programmable logic controllers". Tata McGraw-Hill Education.